No products

Prices are tax included

Categories

- Greenhouses

- Ecoslider Slider 2m

- Ecoslider Slider 2.5m

- Ecoslider Slider 3m

- Ecoslider Slider 3.5m

- Ecoslider Slider 4m

- Shelves

- House Lux Plant staking kit

- House Lux decorative finials

- Slider Plant staking kit

- Longitudinal shelves House Lux

- House Plant staking kit

- H-profiil – 4 / 6 / 8 / 10 / 16 mm

- Protective tape – 38 mm

- U-profile - 4 / 6 / 8 / 10 / 16 mm

- Aluminum U-profile – 10 / 16 mm

- Aluminum pressure profile

- Protective tape – 28 mm

- Set of thermal washer for polycarbonate

Request a special offer

Why customers choose us?

1. Highly durable and reliable greenhouses

All greenhouse models offered by our company were designed for use in northern countries with cold climate and snowy winters.

Our greenhouse frames are not made of ordinary bows or profiles, instead we use patented beams. The beam is a bow or a greenhouse element with an internal weaving and reinforcements, which distribute the load and strengthen the whole construction. Thus there is no need to remove snow from the greenhouses in winter, since the greenhouse are able to withstand heavy vertical loads.

During last few years our greenhouses were purchased both by professional and amateur farmers from the Baltic States, Scandinavia (including regions beyond polar circle) and European Union member states. We are proud of the fact that we have not received any complaints about greenhouses collapsing or being damaged in long winters with a large amount of precipitation!

2. Experience and use of quality materials

To create any quality product, quality materials and parts must be used in manufacturing of the product.

Cellular polycarbonate is one of the most important components of a greenhouse. We have a vast experience in working with polycarbonate of various brands from leading European manufacturers. We use a highly impact resistant and rigid polycarbonate, which is hail resistant, has excellent heat insulation characteristics and is naturally transparent. These products are supported by manufacturer's warranty for a minimum of 10 years and protected against loss of mechanic, optical and thermal qualities due to effects of weather conditions.

Another important part is the greenhouse frame material. Our greenhouses are made of galvanized steel with high zinc proportion that protects the frame from corrosion for decades and increases the service life of the greenhouse. Analogous material is used for roof cover and rainwater drain manufacture.

In manufacturing of EcoSlider greenhouse components (except EcoSlider EL) we chose stainless steel rivets since they have better durability characteristics and their rigidity affects the quality of the whole construction. All fixtures (hinges, bolts, nuts, pressure strainers, screws, magnets) are galvanized.

Our company employees are experienced and qualified in greenhouse manufacturing. This is one of the key factors to ensure production of a quality product.

3. Patented shapes, technologies and trademark

In design of greenhouse shapes and sizes our company experts, first of all, take into account wishes of our clients and market needs. After designers have "created" the model in drawing, our constructors and engineers begin their work. Their main task is to bring the EcoSlider's (Heikkinen OÜ) concept to life – creation of a durable and reliable greenhouse. Construction drawing is transferred to parts drawings, necessary calculations and corrections are made, and manufacturing process technology is implemented. Experimental samples, which will be later improved upon, are made and tested for winter conditions, and only after extensive testing the mass production begins.

Our greenhouse components and manufacturing methods and technologies are patented and protected by law. Ecoslider trademark is also protected by law.

4. Long-term warranty

- General warranty for our greenhouses, including moving elements: doors, vents, sliders, locks, hinges, etc. is 2 years.

- Manufacturer's warranty for polycarbonate - 10 years

- Warranty for galvanized steel beams - 10 years.

Our company manufactures greenhouses and we always have all parts and elements of greenhouses available in our warehouse, as well as full assortment of additional materials. We take our warranty obligations very seriously and we rapidly react to signals of our clients and partners.

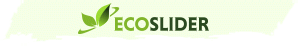

5. Variety of greenhouse models and sizes

- Do you wish to have a practical arch shaped greenhouse in your garden?

- Do you like classic span-roof greenhouses?

- Do you want to build a lean-to greenhouse on your house wall?

- Do you require a greenhouse of custom size and shape?

- Do you plan to professionally grow plants and vegetables in a large industrial greenhouse?

Our company manufactures all abovementioned types and forms available in large assortment of length and width combinations.

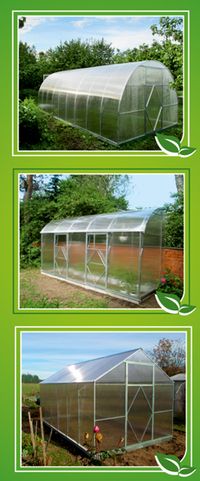

Usually we offer four greenhouse types (depends on the model):

BASIC - greenhouses equipped with 4 mm thick polycarbonate cover and metal foundation with additional reinforcements and 1 meter distance between beams;

STANDARD – greenhouses equipped with 4 mm thick polycarbonate cover and metal foundation with additional reinforcements and 66 cm distance between beams;

PREMIUM – greenhouses equipped with galvanized steel formation, 66 cm distance between beams and 6 mm polycarbonate cover, which increases heat insulation and durability of the greenhouse;

EXCLUSIVE – a more durable and warm greenhouse model with 8mm polycarbonate cover, 66 cm distance between beams, additional uniform and perforated antiDUST protective ribbons and U-profiles.

PRO - the most durable and warm greenhouse model (available upon request) with 66 cm distance between beams and additional reinforcements with a sturdy 10 mm thick polycarbonate cover, which allows to heat the greenhouse during the cold months of the year. The greenhouse is equipped with additional polycarbonate protection in form of uniform and perforated AntiDUST ribbons and U-profiles, as well as the special heat insulating filler for foundation frame.

Our customers can also order a heated or extra durable greenhouse. Maximum polycarbonate thickness for arch shaped greenhouses is 10 mm, however the span-roof models can be equipped with 16 mm thick polycarbonate.

6. Easy and convenient assembly

Our greenhouses are designed in a way that allows the customer to assemble and install the greenhouse on their own without any special skills or preparation.

Each beam is made of two or four segments (two top and two bottom), which can be assembled in 5 minutes. Each greenhouse end consists of four parts: left and right sidewall, a door and an upper arch. Polycarbonate is installed in greenhouse ends and doors during manufacturing process in a factory, thus there is no need for customer to cut the polycarbonate and spend hours on installation of the polycarbonate cover on greenhouse end frames (apart from model EcoSlider EL).

The greenhouse set also includes foundation segments, polycarbonate sheets, a set of fixtures and a detailed step-by-step assembly manual.

For example, the assembly and installation of the popular arch greenhouse EcoSlider 6m X 3 m will take a person without previous experience up to 5 hours (except EcoSlider EL mode).

The customer can also order greenhouse assembly and installation services at the desired location, which will be performed by our experts (this service is available upon customer's request: all industrial greenhouses can be installed in European Union member states by our experts, all hobby-type greenhouses can be installed by our experts within Estonia).

7. Foundation frame

Greenhouses are equipped with a foundation frame made of galvanized steel with increased zinc amount.

A greenhouse with foundation frame can be installed directly on the ground surface or on an existing block or concrete foundation.

All foundation frames are equipped with galvanized fixtures and long anchors to ensure stable attachment to the ground.

Foundation frame is a unique feature that makes our products different from our competitors' products. The foundation frame ensures stable attachment of the greenhouse to the ground (greenhouse will not be "blown away" by strong winds), all frame parts are precisely installed, and the high level of zinc will ensure long service life of the foundation.

8. Manual and automated ventilation solutions

Good ventilation inside a greenhouse is one of the most important factors for a rich harvest.

Standard ventilation solutions offered by our company are greenhouse end windows, which, usually, are located on the greenhouse doors, and greenhouse doors themselves.

Roof vents with reinforced automation Bayliss MK7 Triple Spring are an automated ventilation solution. These vents can be equipped on any greenhouse model.

9. Automatic watering solutions

Timely plant watering in right amounts and periods of time is an important factor for successful harvest.

Standard solutions provided by our company are the automatic micro droplet watering systems, which consist of a controller and all necessary connections, hoses and drips for watering plants. Watering systems are customized in accordance with the size of the greenhouse, number of beds, and customer's wishes.

Most advanced automated watering solutions allow to control water supply to each individual bed and to automatically increase the amounts of water on extra hot days. It means that tomatoes will be watered at one time, cucumbers at a different time, and peppers at the third time (amount and frequency of watering is unique for each watering zone). This system may sound as complicated, but it can be easily set up in one simple way and does not require any special knowledge.

Main benefits of automatic watering:

• Separate watering times and amounts for each separate bed.

• Water consumption is reduced three times, and the water intake is twice as high.

• Yield is increased with the least labour inputs.

• Sicknesses and fungal infections caused by excess humidity on the leaves will not bother you anymore, and the soil will not form a crust that prevents roots from breathing.

• Direct root watering prevents weeds from growing simply due to scarcity of humidity.

This way, by using new watering technologies, our customers can achieve good harvests and reduce amounts of labour input to take care of the plants.

Irrigatia (England) - the most basic system. Plain and reliable, does not require conventional power supply, solar battery powered, controls one watering zone with an option to adjust water supply intensity. Delivers water directly from tank to plants. Can water 12 or 24 plants (depends on the chosen model). Additional set to increase the number of watered plants is available for purchase.

Gardena (Germany) - a system with a removable control panel, which is powered by batteries and controls water supply to two zones. Does not require conventional power supply. Can be connected to a tank, pump or pipeline.

Hunter (USA) - a professional and reliable solution both for standard and industrial greenhouses. A variety of models and options available: sun radiation gauge, remote control, various valve types, water-resistant body, etc. Requires a connection to 220V power supply and a pipeline.

Automatic watering system for industrial greenhouses, usually, includes a control panel in water-resistant body and valves that regulate watering zones, with a built-in filter and reduction gear that levels the system pressure and prevents it from clogging. The described equipment is sold by our company.

10. Special polycarbonate protection

Use of polycarbonate sheets in any constructions requires paying particular attention to protection of polycarbonate edges with open cells. If the said edges remain unprotected, the cells will be clogged by dust, dirt and insects, condensate will form inside, which will cause formation of mould. Polycarbonate will become visually worse (starts to turn green), polycarbonate structure will deteriorate and affect the durability of the whole construction.

Our company offers special uniform and perforated AntiDUST ribbons manufactured by a Dutch company Multifoil and U-profiles to protect polycarbonate cover for many years, thus significantly increasing the service life.

11. A beautiful and attractive design

For many of our customers the decisive factor to purchase our greenhouses was the visual look.

The basic greenhouse, with which we began our work, was the arch shaped EcoSlider ES greenhouse. The greenhouse has distinctive, strong beams with original interweaving. The beams are placed at 667 mm distance for the whole frame length and make the whole construction visually powerful and durable.

Galvanized steel foundation also adds to elegance by being in perfect harmony with the whole frame.

Taking into account wishes of our clients, we have designed span-roof, lean-to and industrial greenhouses as well as mini-greenhouses, which are equipped with original, reliable beams (apart from mini-greenhouses) with interweaving, which makes them to stand out among products of other companies.

Automatic roof windows equipped with special thermal cylinders are not only elegant, but also very practical since the greenhouse is able to ventilate itself with no involvement of the owner. Automatic watering system turns an ordinary greenhouse into an autonomous growing system.

12. Superior quality for available price

The main principle of our company is to offer highly durable and reliable greenhouses. We use only quality materials and supplies in our manufacturing process. Our constructors and technical staff are constantly developing new greenhouse models, while improving the existing models and manufacturing processes at the same time.

All our greenhouse models are beautiful and elegant, equipped with various ventilation and automatic watering solutions. We also offer special protection for polycarbonate covers, greenhouses are easy and convenient to install, while a long-term warranty is provided for every model.

A variety of various greenhouse models at every price level is available to our customers: BASIC (the lowest price model), STANDARD (basic), PREMIUM (more durability and warmth), EXCLUSIVE (increased durability and warmth) and PRO (the most durable and warm model).

13. Flexible payment terms

Our company offers our customers two options to pay for greenhouses in instalments. First option – a short-term direct lease from the manufacturer with 6 months payment period and zero interest rate, second option – a long-term lease from 7 to 24 months.